PWT auto XCS automatic welding system

Automatic pipeline welding with consistent quality, built‑in control, and field‑proven productivity.

Automatic welding system

The Qapqa PWT auto XCS automatic welding system is designed for pipeline welding with high performances and advanced welding arc control features. The Qapqa PWT auto XCS welding system is reliable and flexible using a special process for root-pass welding (with or without copper backing), Advanced Pulse for fill/cap and FCAW for tie-ins and crossings. Delivering repetitive quality results from root to fill and cap, with less variability, less rework, and more uptime.

Features

- Advanced Pulse arc control for stable and efficient deposition.

- Through the arc seam tracking with precise torch guidance.

- Automatic CTWD* (Contact Tip to Work Distance) adjustment for consistent arc length.

- Automatic gas mixer (Ar/CO₂) with electronic control.

- External display to monintor real time parameters.

- Dual welding bugs (left/right interchangeable) for flexibility on site.

Technical highlights

- Pipe diameter range: 6″ and up

- Welding positions: 1G / 5G / 6G

- Processes:

- Root: RMD (no copper support) or GMAW (with copper support)

- Fill/Cap: Advanced Pulse GMAW (A‑GMAW) or mechanized FCAW (M‑FCAW)

- Tie-ins and crossings handled with precision, reducing manual intervention

- Operating temperature: −30°C to +60°C

- Torch inclination: ±15° (±1° accuracy)

- Tilt sensor: ±1° accuracy

- Oscillation amplitude: 0–25 mm; Dwell: 0–2s

- Wire feed: 0–16 m/min; Travel speed: 0–150 cm/min

- Minimum cutback: 140 mm (bevel to coating); 305 mm (bevel to concrete)

- Power: 400 V AC (±10%), three‑phase (control box); 24 V components where specified

Why PWT auto XCS welding system?

- Predictable quality, pass after pass

Advanced Pulse for fill- and cap pass, combined with a specialized root pass process with or without copper backing, stabilized heat input and bead formation. This reduces spatter, undercut, and lack of fusion providing consistent and high-quality welds. - Fewer variables to manage

Automatic CTWD maintains the correct arc length. Seam tracking keeps the torch on course. The integrated dual gas mixer for Argon and CO₂ delivers consistent shielding gas blends, reducing operator variability and providing repeatable quality. - Real‑time control

The control box of Qapqa PWT auto XCS system is equipped with external displays for continuous supervision of welding parameters. Additional integrated displays on each spool holder provide localized monitoring and parameter adjustment inside the welding tent. This real-time feedback loop allows operators to immediately detect and correct deviations, ensuring weld quality and reducing the risk of defects. - Designed for all conditions

The control box is IP23 rated and the bugs and spool holders are IP54 rated. Combined with an operating temperature range from −30 °C to +60 °C, the system keeps you welding reliably in extreme climates. - Consistent motion, consistent welds

All motion axes use digital stepper motors to support precise and repeatable wire feed, travel, oscillation, and torch positioning. This consistency is key to achieving uniform penetration and a stable bead shape. - Faster setups, less downtime

Two interchangeable left/right welding bugs with ergonomic design mount quickly on the guide ring. Inside the welding tent, standard 15–18 kg spools and local parameter access keep operators productive. - One system for root to cap, tie‑ins and crossings

Perform every weld pass with our welding system. Use RMD or GMAW for the root, with or without copper backing, and switch to Pulse GMAW or mechanized FCAW for fill and cap. This approach reduces hand‑offs and eliminates unnecessary equipment changes.

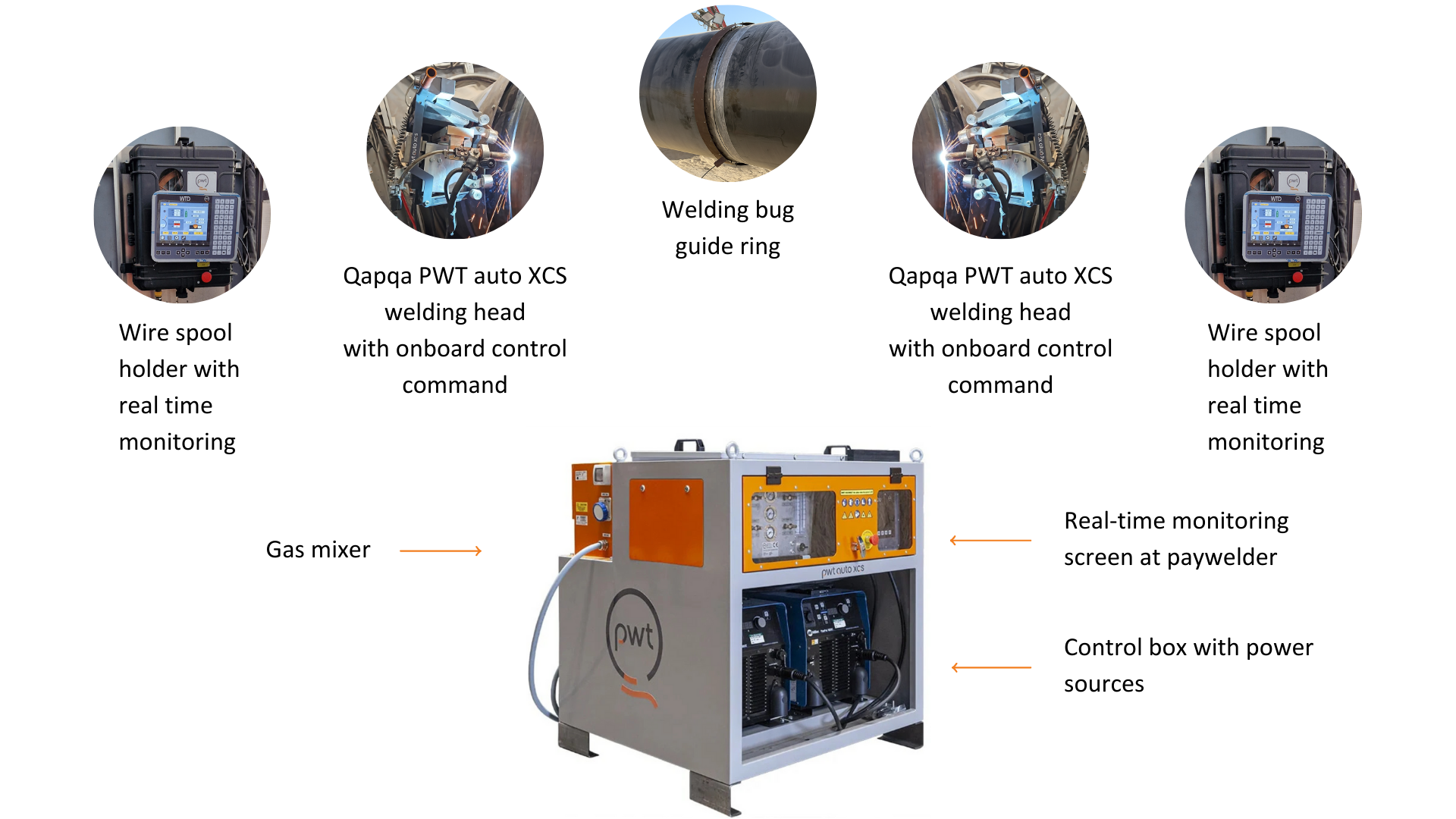

Automatic welding system components

The PWT auto XCS is built from rugged, field-proven components engineered for pipeline construction in any environment:

- Control box with dual power sources, electronic PSU, and integrated Argon/CO₂ gas mixer

- Two identical welding bugs (interchangeable left/right) with a quick-mount guide ring attachment system

- Two wire spool holders with integrated parameter displays for real-time monitoring and adjustments inside the tent

- Guide ring system for precise welding bug travel and positioning