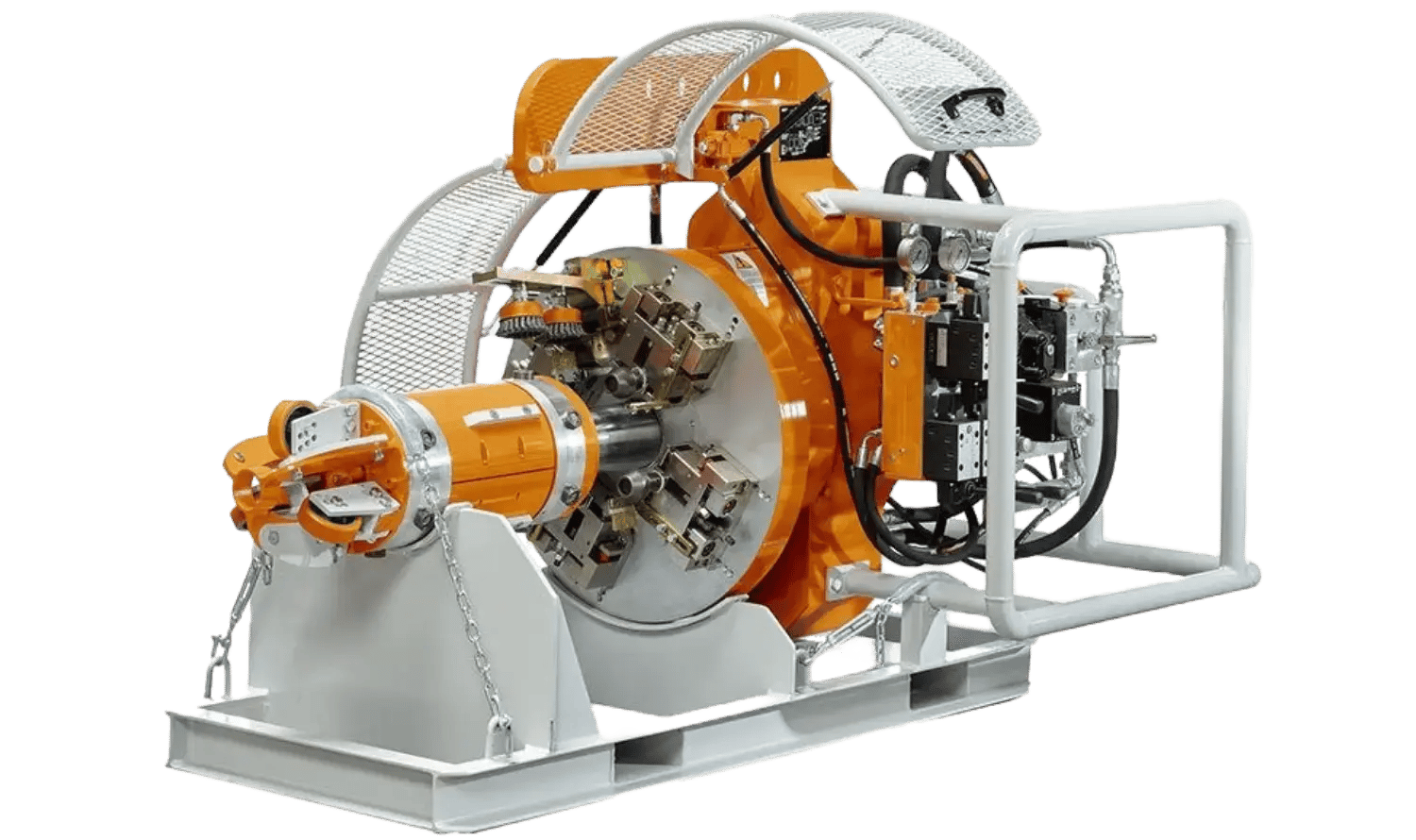

Pipe Facing Machine - PFM

PIPE FACING MACHINE

The pipe facing machine prepares the pipe for the welding process. Diameter range 8-100"

Qapqa’s Pipe Facing Machines (PFMs) are engineered for high-performance pipeline welding operations. Designed for both automated and manual welding, these machines deliver clean, accurate bevels that reduce weld time, improve joint integrity, and minimize rework.

Whether you're working with heavy-wall pipes, transition joints, or differing pipe grades, the PFM ensures consistent results

Purpose-Built for performance

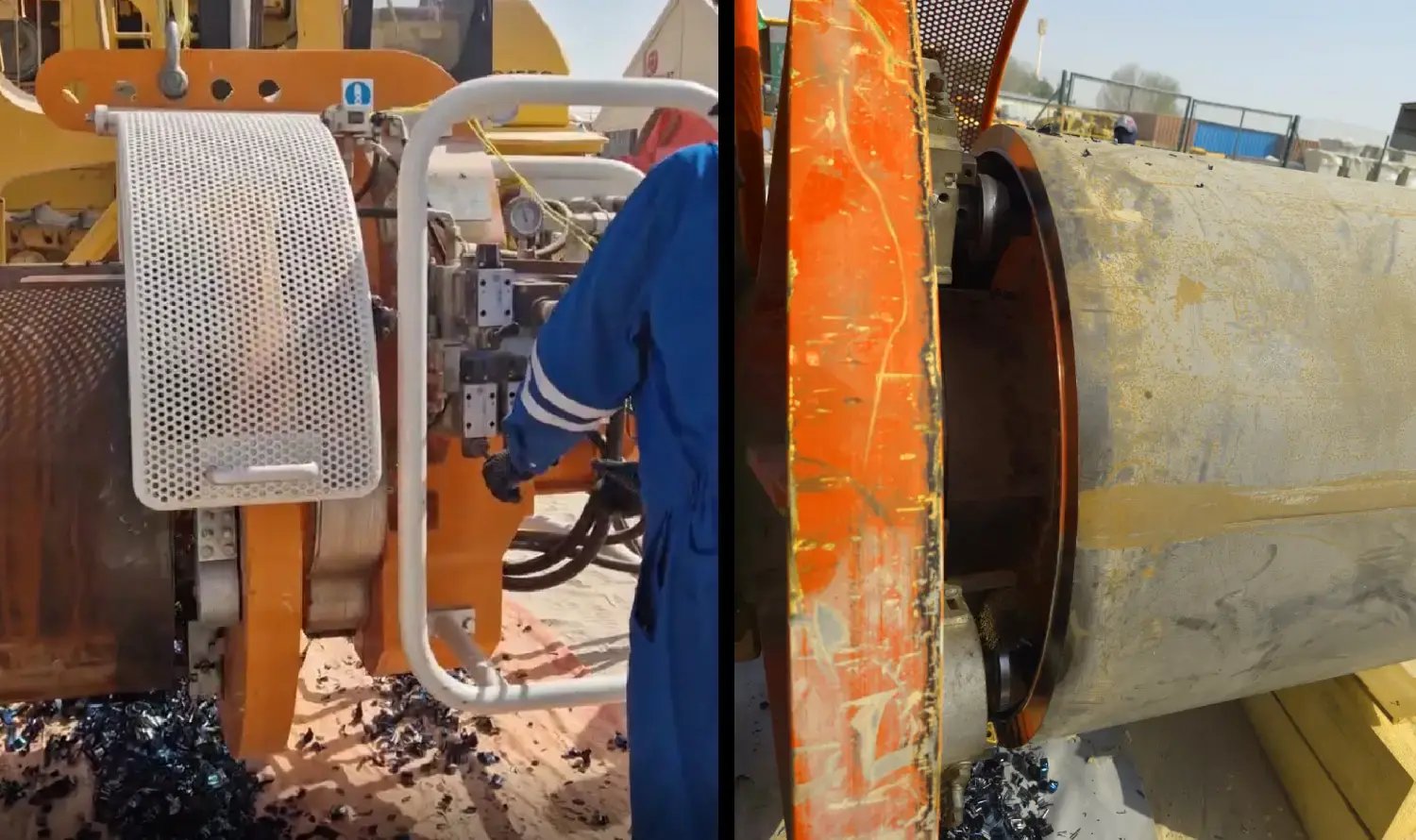

Each PFM is designed to machine accurate bevels that meet the requirements of automated welding systems and manual welding operations. From clean bevels that reduce repair work to transition tapers for joining pipes of different wall thicknesses, Qapqa’s PFMs deliver consistent results under pressure.

The machines are powered hydraulically—either via a diesel or electric power unit, or directly from existing equipment such as pipelayers or excavators, eliminating the need for additional adapters.

Modular range for every pipe size

Qapqa offers a full range of PFMs, each optimized for a specific pipe diameter:

- PFM 08–16"

- PFM 10–20"

- PFM 16–24"

- PFM 24–36"

- PFM 48–64"

- PFM 74–88"

- PFM 80–88"

Each model features a dedicated clamping and machining section, with interchangeable components to support various bevel configurations and pipe grades (API-5L X55 to X80).

Engineered for efficiency

- Cutting Speeds: Up to 195 m/min depending on model

- Bevel Tolerance: ±0.1 mm for consistent weld prep

- Tool Holders: 3 to 6 per machine, each with tungsten carbide cutting tips

- Wall Thickness Capacity: Up to 35 mm

- Operating Conditions: -25°C to +50°C, up to 3000m altitude

The hydraulic control panel allows precise adjustment of feed rate, rotation speed, clamping pressure, and emergency stop functions—ensuring safe and efficient operation in the field.

Optional features & accessories

- Internal counterboring tools

- Coating removal systems

- External brush adapters

- Special shoes for concrete, FBE, and stainless steel pipes

- Guide rollers for stainless steel

- Certified operator training is available, covering safe operation, routine maintenance, and troubleshooting

- Container box for transport and storage (up to 42" models)