Al Turki - Rahab Harweel Integrated Project (RHIP)

Company: Al Turki

Type: Gas pipeline

Country: Oman

Material: X65

Client: PDO

Diameter: 6"- 20”

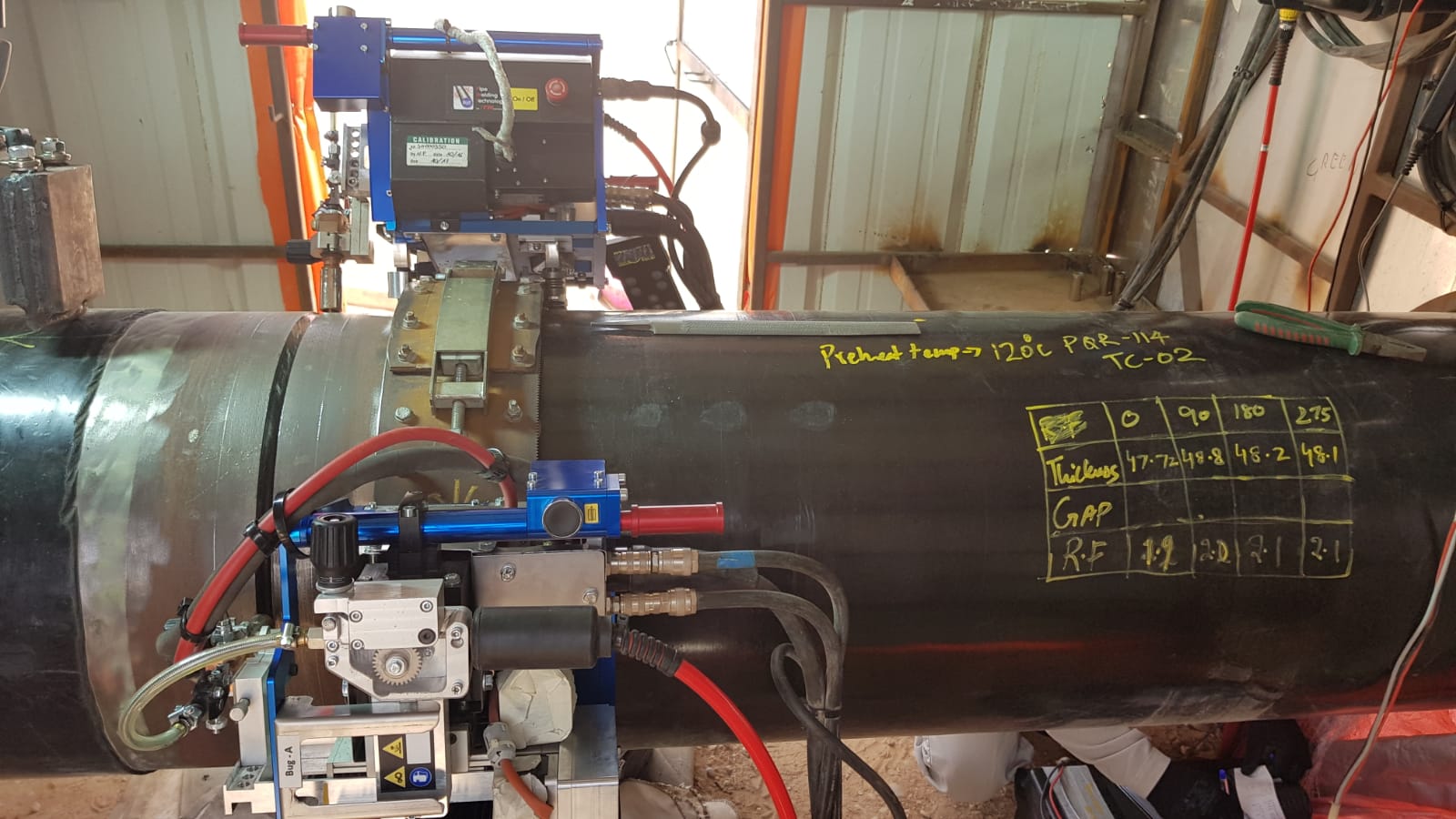

WT: 12 - 50 mm

Distance: 67 & 96 km

Characteristics

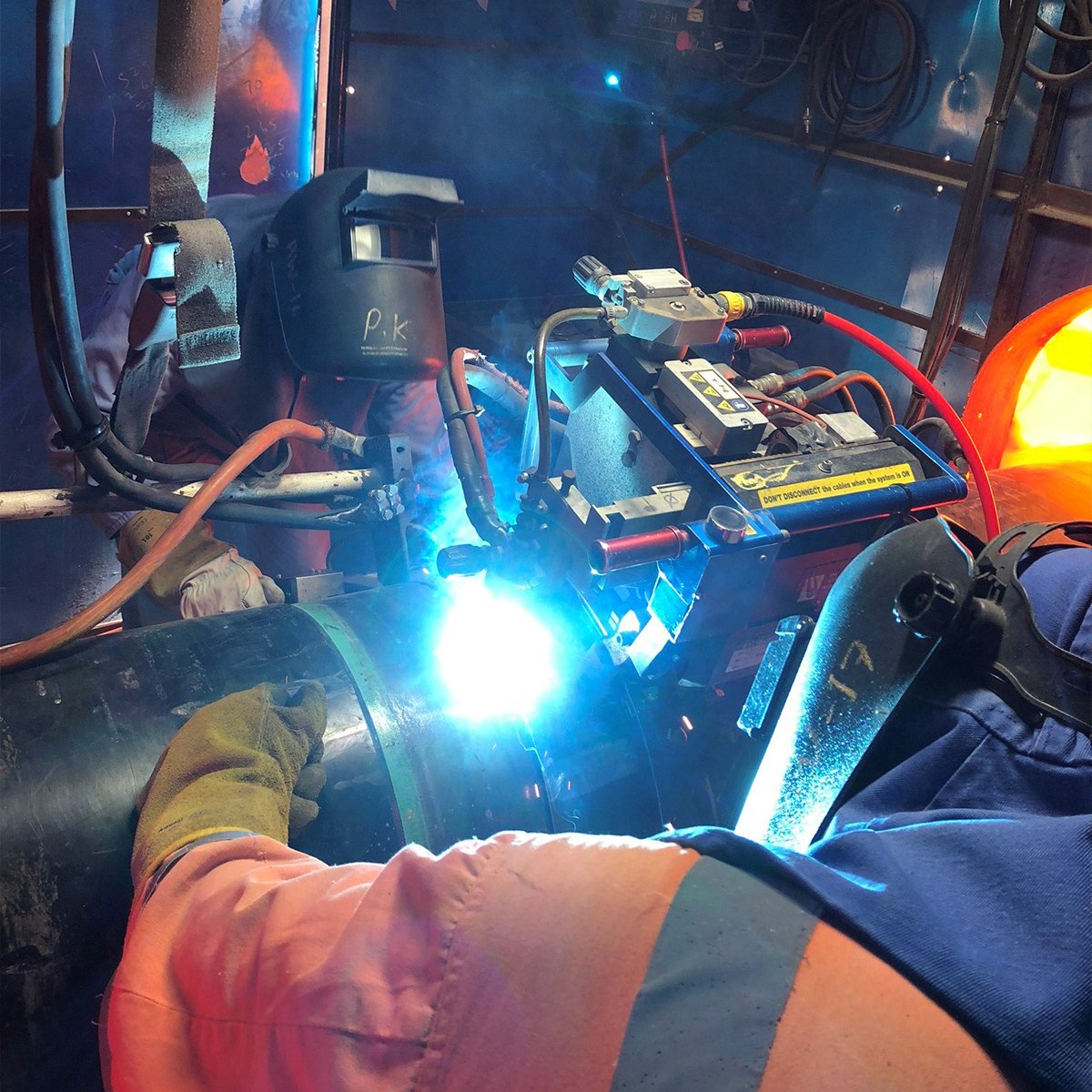

- Automatic welding of the root-pass with copper backing.

- Filling/capping with Advanced Pulse (P-GMAW)

- Wall thickness up to 50mm

Rabab Harweel Integrated Project (RHIP) – Oman

In 2019, Al Turki Enterprises, together with Qapqa, completed the Rabab Harweel Integrated Project (RHIP) two months ahead of schedule. This state-of-the-art gas pipeline project was strategically designed to enhance gas transportation from the Rabab and Harweel reservoirs, supporting PDO’s upstream and midstream operations.

About Al Turki Enterprises

Al Turki Enterprises is a leading Omani company providing construction, commissioning, and maintenance services for the oil & gas and energy industries. Our philosophy is simple: people and technologies are the key to operational excellence.

Rabab Harweel Integrated Project

The RHIP pipeline network spans 67 km and 96 km, transporting natural gas efficiently from the reservoirs to processing facilities. The project uses X65 steel pipes, ranging from 6" to 20" in diameter, with wall thicknesses of 12–50 mm.

Al Turki deployed PWT’s XCS automatic welding system, delivering automated, high-integrity welding performance for critical gas infrastructure in challenging desert conditions and high-spec energy operations. This advanced technology enabled the team to overcome the challenging terrain and maintain safety and efficiency throughout construction.

This modern gas pipeline project demonstrates Oman’s growing capacity to deliver world-class infrastructure. By combining Al Turki Enterprises’ engineering expertise with Qapqa's advanced welding technology, the RHIP pipeline strengthens local capabilities, creates skilled jobs, and ensures safe and efficient gas transportation across the region.